Belt Automation Centralized Control Unattended

Product Description

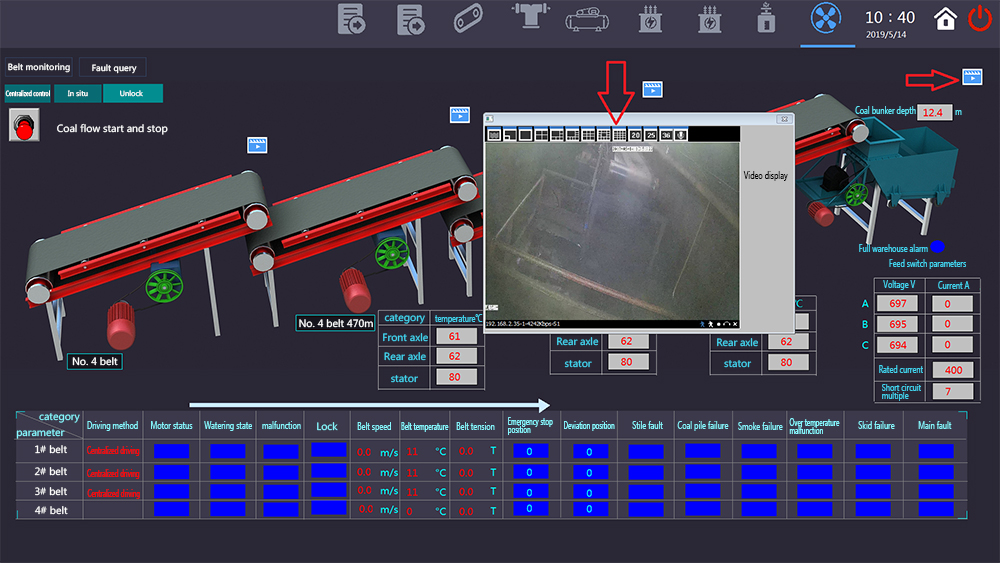

Belt Automation Centralized Control unattended

■ System overview

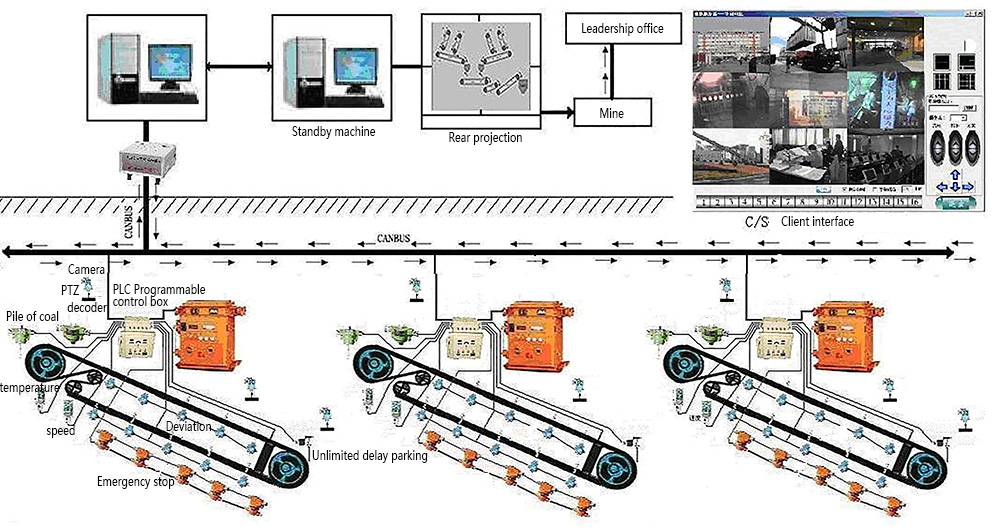

Belt conveyors and transfer conveyors have become very important transportation equipment in coal mine production. Whether it can operate safely and efficiently directly determines the startup rate and output of mine electrical and mechanical equipment. With the rapid development of computer technology, various belt conveyors The functions of machine protection sensors are constantly improved. The world ’s advanced coal mining countries use computer control technology, network technology, fiber optic communication technology and sensor technology to implement remote centralized control of underground belt conveyors on the ground. According to the characteristics of coal mines, efficiency is reduced according to the reduction of staff. Reliable and advanced design principles. The intelligent belt conveyor centralized control and monitoring system developed by our company is a high-tech product applied to the automation of mine belt transportation. This system is based on the "Coal Mine Safety Regulations" and summarizes the emergence of mine transportation The accident of the new generation is based on the characteristics of high safety, practicality and advanced features.

The system fully considers the actual working conditions of the underground and underground, and uses advanced technology, mature equipment and sensors. The core part of the main control station and sub-stations uses the KXH18 mining intrinsically safe programmable controller independently developed by the company. The control network adopts Optical Fiber transmission, which is stable and reliable, and has strong anti-interference ability. When the control network is paralyzed, there are emergency measures for centralized and local control methods. Due to fault finding or troubleshooting, when the belt needs to be started temporarily, unnecessary protection signals can be temporarily shielded by the upper computer, and everything will be restored after normal.

The system uses redundant technology in the control system to realize that the ground control center computers are hot standby for each other and improve the reliability of the system. Considering the scalability of the system in the future, it can easily integrate future coal transportation equipment into the existing system, and expand the system to achieve longer-range monitoring. All master stations and substations use industrial Ethernet transmission, which can be arbitrarily connected to the underground industrial Ethernet ring network (1000M network). This centralized control system is mainly based on the ground centralized control operation, which realizes the operation control and data monitoring of the entire coal transportation system. Both centralized control and single belt local control are available. The stop of any one of the coal transportation equipment will cause the subsequent transportation equipment to stop and realize the blocking function.

■ System functions

The system has continuous quantity detection of speed, temperature, current, etc. By the system speed sensor signal detection, can perform slip, overspeed, underspeed and broken belt protection. The system can also calculate the bearing temperature, winding temperature, and roller temperature of the motor.

Line detection and display. Set the alarm value and stop of each continuous quantity in the parameter menu.

After the machine value, once it reaches the alarm value, it will automatically alarm, if it exceeds the shutdown value, it will automatically stop( of course, it can also be set to alarm only, not stop). The belt machine has a start early warning signals, deviation, emergency stop, sprinkler, smoke, speed, coal pile, longitudinal tear, temperature and other protection.

(1) Data acquisition function;

(2) Monitoring and protection functions;

(3) Control system communication function;

(4) Control system display function;

(5) Real-time (historical) curve display function;

(6) System startup and shutdown functions;

(7) Fault self-diagnosis function.

■ System characteristics

● Full industrial grade products, suitable for long-term work and use in the harsh environment of coal mines;

● It has multiple safety designs such as early warning of equipment startup and maintenance lockout to ensure the safety of maintenance personnel and equipment operation;

● The system has multiple operation rights such as query authority, operator authority, engineer authority, etc., each with different operation authority;

● The query authority can only query system operating parameters and working conditions, and can generate various reports based on relevant parameters and data, but has no right to control system equipment and adjust system parameters;

● The system provides OPC data interface, which is convenient for accessing the future mine automation information platform;

● Modular design, reserved expansion port, you can add monitoring points and monitoring items at any time to expand the monitoring system;

● Display the fault location, cause, type, etc., and upload it to the ground dispatch center;

● With safety lock function during maintenance;

● Realize multiple control outputs, start or stop related facilities (some outputs have delays, and the delay time is adjustable);

● It has protection measures to select the operation mode and prevent unauthorized operators from operating at will;

● It has a fault shielding function. When the tape needs to be temporarily activated due to fault finding or troubleshooting, it can temporarily shield unnecessary protection signals and recover after everything is normal. The system has good scalability and can be easily upgraded and upgraded.

● In addition to the query authority, the operator authority also has the authority to operate system equipment, but has no authority to adjust system parameters;

● In addition to the operator authority, the engineer authority also has the authority to adjust the system parameters;

● Programmable automatic production mode, can set various startup modes;

● The monitoring picture is dynamic and vivid, and the running status of each device of the module is real-time;

● Simple and fast operation, non-professionals can operate after simple training;

● The main control equipment and Communication Module have a self-detection function, and can give an alarm in time when there is a problem with the equipment;

■Our Company

Jinzhou Jinshi Mining Equipment Technology Co., Ltd. is located in the beautiful coastal city of Jinzhou, specializing in mining communication products and coal Mine automation equipment design and development, production and sales, contract installation related to coal mine safety production monitoring and monitoring system, solutions, after-sales service, etc.

Product Categories : Coal Mine Automation Unattended > Belt Automation Centralized Control Unattended